Product Consultation

Your email address will not be published. Required fields are marked *

The Pain Points Plaguing Global Energy Management

The traditional "one meter per device" model remains a major bottleneck for energy management efficiency worldwide. A data center operations manager in North America shared a typical scenario: monitoring 20 server racks would require 20 separate meters, occupying over 50% of the distribution cabinet space and driving up cabling costs significantly. Worse still, manual meter reading leads to delayed data, and by the time energy anomalies are detected, unnecessary waste has already occurred.

According to the International Energy Agency (IEA) report Data Centers and Data Transmission Networks, global data center energy consumption is projected to reach 1,100 TWh by 2030—equivalent to the annual electricity demand of Japan and Germany combined. Against the backdrop of global carbon neutrality commitments, enterprises urgently need solutions that balance precise energy monitoring with cost control. This is where Eastron MCS solution steps in.

Eastron MCS Solution: One System, Full-Site Coverage

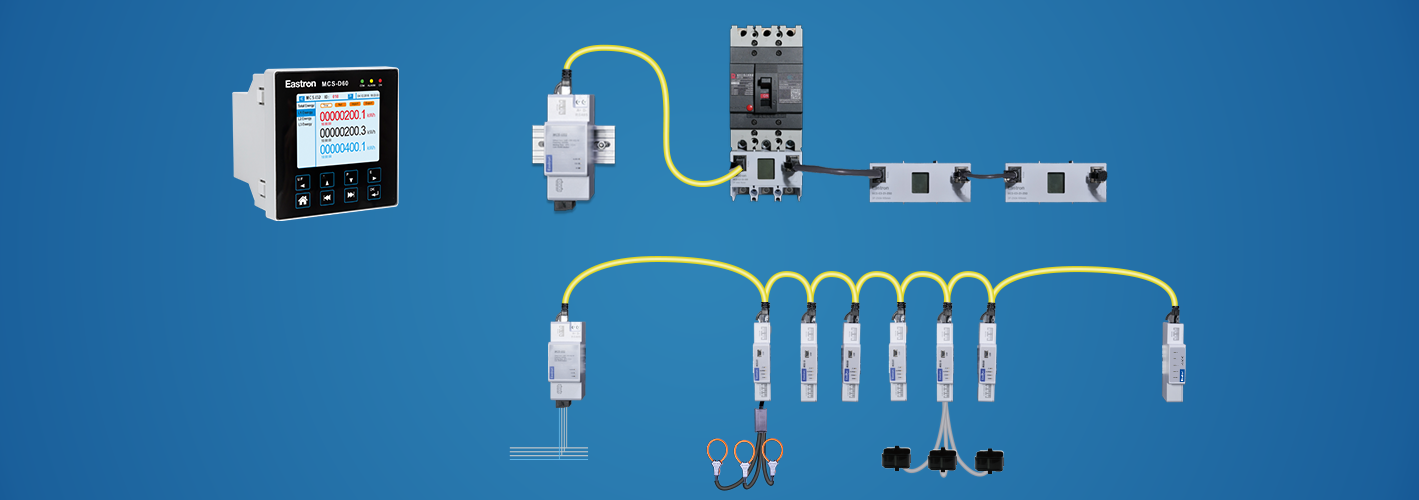

Eastron MCS Multi-Circuit Measurement Solution completely abandons the outdated "one meter per device" approach. As an integrated modular system, it combines 6 core modules to cover the entire workflow—from voltage/current monitoring to anomaly alerting—via flexible configuration.

Its distributed installation design is a game-changer: no redundant devices are needed, as one MCS system can monitor energy use across multiple pieces of equipment. This cuts overall costs by over 50% and reduces installation space by 80%. Critically, accessing the built-in WEB server allows users to:

View real-time data from all modules

Remotely configure module parameters

Perform data analysis and check Sequence of Events (SOE) records

This transforms energy management from "reactive troubleshooting" to "proactive control."

6 Modules: Flexible Combination for Complete Systems

It is important to note that while the 6 modules support customized combinations, two types are mandatory for system operation:

MCS-U (Voltage Measurement Module)

At least one current measurement module (MCS-I or MCS-E; mixed deployment is also supported based on on-site needs)

Other modules can be added based on functional requirements, and all work together to form a complete measurement system.

|

Module |

Core Functionality |

Key Features & Application Notes |

|

MCS-D |

Data Display Parameter Configuration 1GB memory Ethernet Gateway Supports Data Analysis and SOE Viewing |

The "brain" of the system, managing data interaction across all modules (no scenario restrictions) |

|

MCS-U |

Voltage Measurement Power Supply for Other Modules Supports 1P2W/3P3W/3P4W RS485 Communication |

Only 1 unit is needed per system Power MCS-I/E/IO/R modules |

|

MCS-I |

Current Quality Analysis Anomaly Alerting Supports 1x3ph/3x1ph Current Transformer Connection Built-in USB Port |

Mandatory (or mix with MCS-E) No installation location limits (can be centrally deployed and connected to monitored devices) Ideal for data centers |

|

MCS-E |

Current Measurement (Built-in Current Transformer) Supports Multiple Wiring Modes LCD Screen for Local Display |

Mandatory (or mix with MCS-I) Must be installed under circuit breakers Maximum of 24 units three phase or 72 units single phase circuits Ideal for industrial scenarios |

|

MCS-IO |

4 Digital Inputs (DI) + 2 Digital Outputs (DO) Monitor the Status of Third-party Devices (e.g., Circuit Breakers) |

Optional Works with MCS-U/I/E to trigger automatic alerts for anomalies (e.g., circuit breaker status warnings) |

|

MCS-R |

Bus Repeater with 230V input |

Optional Up to 4 units can be installed Max transmission distance: 500m Activate when total power consumption exceeds the auxiliary power supply limit |

Update your energy management with Eastron MCS Solution

The global energy monitoring market is expanding rapidly—Grand View Research projects it will reach USD 34.5 billion by 2030 (up from USD 18.2 billion in 2023). Eastron’s MCS solution leverages a "modular + centralized" approach to help enterprises capture key benefits:

50% lower installation costs

100% higher operational efficiency

Data-driven energy savings opportunities

Whether for high-density rack monitoring in data centers (using only MCS-I), circuit breaker-mounted loop management in industrial sites (using only MCS-E), or complex scenarios with both racks and industrial equipment (mixed MCS-I/E deployment), MCS delivers precise, tailored performance.

Contact us to get your customized energy management solution from Eastron!

Your email address will not be published. Required fields are marked *

We develop and produce high performance electricity meters, power analyzers, current sensors, communication modules and management systems. China Custom Smart Meters Manufacturers and Factory

Address:NO 52, Dongjin Road, Nanhu, Jiaxing, Zhejiang, China

Copyright @ Eastron Electronic Co., Ltd. All rights reserved Electricity Meters Manufacturers